HD Hyundai Construction Equipment's mobile website is optimized for portrait (vertical) view.

Environment (E)

Each year, HD Hyundai Construction Equipment establishes safety, health, and environmental policies and goals, communicates them to all business sites and employees and encourages company-wide participation.

Environmental Management Strategy

Policy

Develop eco-friendly products and strengthen low-carbon production activities

Prevent environmental pollution and conduct activities to achieve continuous improvement

Core Values

Strengthening greenhouse gas (GHG) management

Strengthening ESG management

Complying with and continuously strengthening environmental standards

Responding to environmental regulations

Undertaking environmental pollution prevention activities

Environmental Management Policy

HD Hyundai Construction Equipment has formally endorsed international declarations and standards concerning the environment and established the Environmental Management Policy in 2023 to prioritize the realization of social value based on environmental management. The Environmental Management Policy is designed to minimize negative impacts on the environment and contains information on the environmental management organization, products, production environment, and management environment.

Main Contents of the Environmental Management Policy

Environmental Management System

Product Environment

Production Environment

Management Environment

Chemical Management Policy

Reducing environmental risks and preventing environmental accidents

A legal

Response

Packaging

Responding to Environmental Laws and Regulations

To align ourselves with environmental laws and regulations, which are becoming increasingly stringent, and to prevent environmental accidents, we regularly inspect environment-related facilities at our workplaces and make efforts to minimize pollution by improving equipment that discharges pollutants such as air pollution prevention equipment and separating recyclables from waste.

We conduct emergency environmental accident response drills based on different scenarios, such as oil leakage and fire, accidents at wastewater treatment facilities, and accidents in confined spaces, in addition to joint fire drills with the fire department.

For each situation, we come up with and implement specific scenarios such as "diesel leakage during oil tank refueling," "joint firefighting activities with the fire department in the case of fire," "interruption in the operation of wastewater treatment facilities due to natural disasters," and "emergency rescue activities in the case of an accident in a confined space. We conduct realistic fire drills to be prepared for fires, which are particularly common.

In order to maximize the effectiveness of our accident response and training, we conduct drills at major locations, measure the emergency response capabilities as an indicator by checking the time it takes to evacuate and gather at the designated assembly point, and conduct drills at each business site. All employees are required to participate in the drills in order to raise safety awareness company-wide.

Environmental Education

HD Hyundai Construction Equipment conducts regular environmental training programs to enhance environmental and safety awareness among field managers and employees. Each year, site-specific training is provided on key environmental issues such as air pollutant emission facilities and wastewater treatment systems. In addition, internal training related to ISO 14001 is conducted to strengthen employees’ practical capabilities and promote effective environmental management.

Environmental Education Programs

| Program | Main contents | Trainees | Training cycle |

|---|---|---|---|

| ISO Standards Implementer Training | Understanding of ISO 14001 (Environmental Management System) standards and requirements | EHS implementers from different departments | Once a year |

| Environmental Facility Operation Manual | Equipment Operation Manual, Workplace Mandatory Guidelines, Legal Compliance Management Procedures | Related Departments, Managers, Workers, and Partners (Subcontractors) | Once a year |

Waste Reduction and Recycling

Waste generated from production and office activities is classified into general waste and designated waste and entrusted to waste treatment service providers for legitimate disposal.

To improve the separation of plastics, cans, bottles, waste paper, and other recyclables before disposal, we have installed collection bins for recyclable waste adjacent to our business sites to enhance accessibility. The recyclables are sold to recyclable collection companies to minimize the amount of waste generated and increase the recycling rate.

Non-recyclable waste is legally disposed of via specialized companies, and preferred contractors are slected whenever possible to minimize the incineration and landfilling of waste, thereby reducing the environmental pollution caused by industrial waste. In addition, we strive to minimize waste by simplifying the delivery packaging of our suppliers, thereby reducing the amount of waste generated at the source.

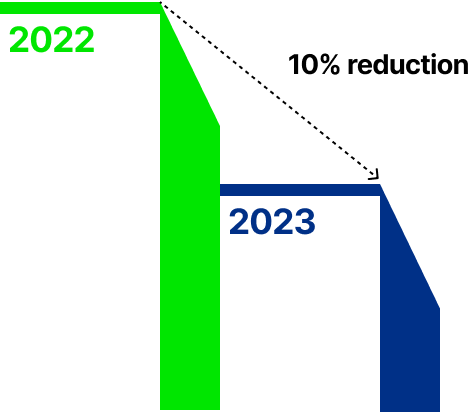

Waste Reduction Target (Unit: kg/unit)

Major Waste Reduction Strategies

| Scrap metal | Waste wood and waste paper |

|---|---|

| Review of recovery plan for ZF (made in India) AXLE pallets | Simplifying and reducing the inventory of wooden boxes and changing packaging containers |

Waste Reduction Performance in 2024 (Unit: kg)

-

Weight of

waste per unit146

-

2024 Target

(Achievement Rate)153

(105%)

Minimizing the use of disposable packaging at Ulsan Campus

Minimize

Packaging

Some of the raw and subsidiary materials delivered to the Ulsan campus are packaged in disposable cardboard boxes.

To reduce waste, we have considered substituting disposable cardboard boxes with reusable plastic boxes and pallets.

In the case of switching to plastic boxes and pallets, the boxes and pallets that the goods are received in can be reused for the next delivery. We listened to the opinions of suppliers that deliver to the Ulsan campus to see if they could change their delivery methods, and while some faced difficulties making such changes, about 24% of suppliers changed their delivery methods.

The reuse of plastic delivery boxes is expected to reduce the amount of waste generated and the burden of disposal, while also allowing our suppliers to save on packaging costs. For suppliers who have difficulty improving their processes due to the costs involved, we are considering providing financial support and continuing our efforts to further minimize packaging.

Process Improvement

Cardboard boxes

Plastic boxes

Pallets