HD Hyundai Construction Equipment's mobile website is optimized for portrait (vertical) view.

Social (S)

HD Hyundai Construction Equipment is committed to delivering greater value to all stakeholders and employees.

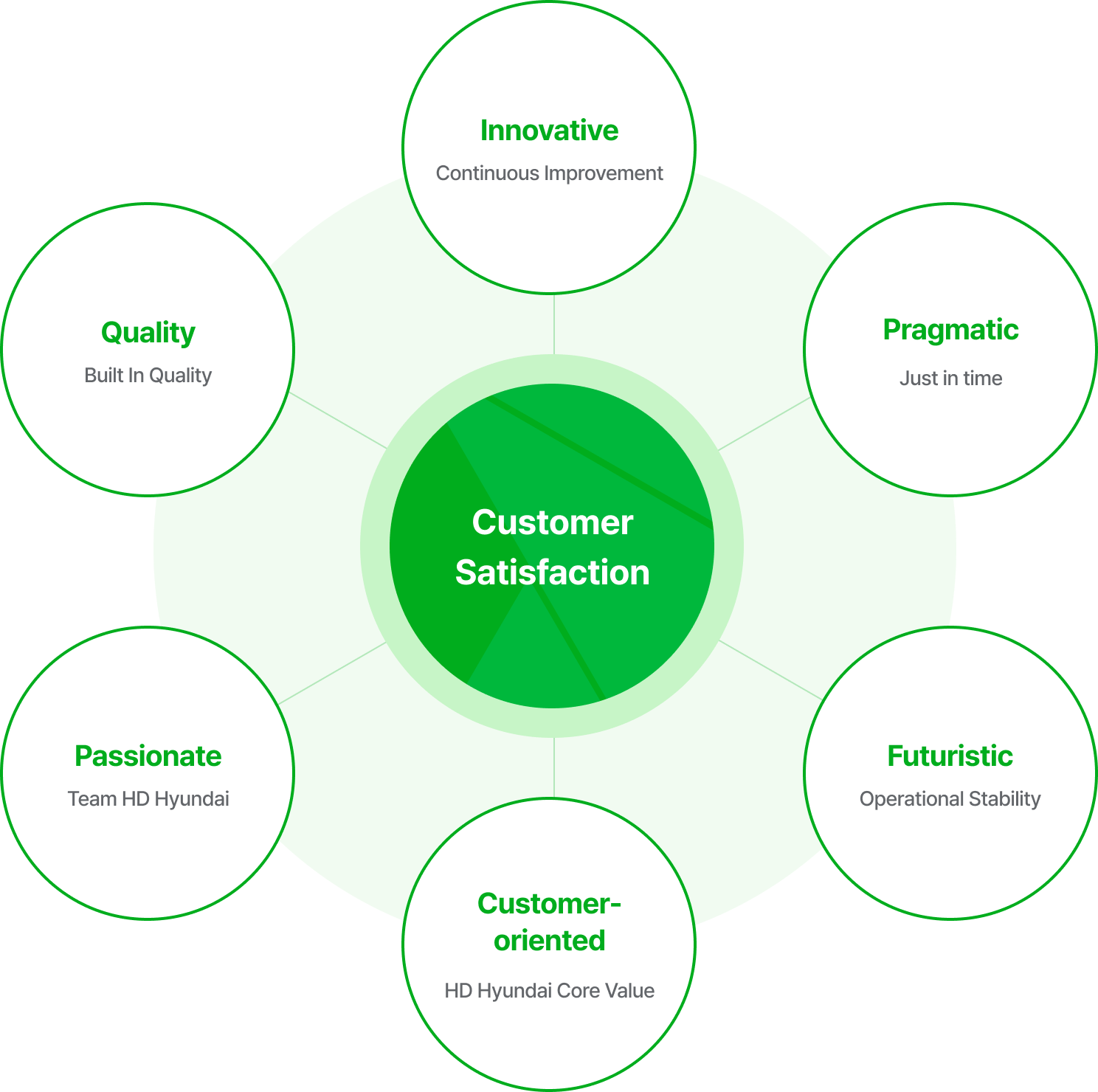

Customer Satisfaction

HD Hyundai Construction Equipment strives to grow as a global company by building long-term relationships based on trust through win-win cooperation that helps our suppliers strengthen their competitiveness.

Quality Management

HDPS

(HD Hyundai Production System)

HD Hyundai Construction Equipment is implementing the HDPS, involving ongoing field-oriented production innovation activities, to gain mid- to long-term manufacturing competitiveness amid growing competition in the domestic and foreign construction equipment manufacturing industry. In early 2022, we set forth step-by-step goals for the Ulsan campus and operated several modules, starting with activities such as material supply, quality, and standardization. The need for change control has been felt by all employees, and voluntary and site-led improvement activities are being actively carried out to realize the ultimate goal of optimized production through leveling, standardization, and fool-proofing of all factories.

Customer Satisfaction

HD Hyundai Construction Equipment's Unique Production System

- Reducing costs by improving manufacturing competitiveness

- Pursuing ongoing field-oriented improvements

- Providing continuity from the bottom-up

Step-by-step goals of production innovation activities

-

STEP 1

Introduction Phase

Reform of awareness

3-jeong 5S

Suggestion system

Small group improvement activities

Reduced preparation time

Fool Proof

Fostering multiplayersCultivate an improvement mindset

Improvement of the basic production environment -

STEP 2

Growth Phase

Reducing lost time in production

Flow production

Tact Time

Line Balancing

Standard operations

Visualization managementTract time production

Streamlining of production operations -

STEP 3

Maturity Phase

Just-in-time (JIT) logistics

Production leveling

Execution and standardization managementJIT production system

Optimized production

Preventive quality enhancement Quality innovation taskforce (TF)

In order to improve persistent quality problems, we have organized the Quality Innovation Taskforce (TF) to focus on addressing key quality issues. Through the operation of four TFs in the areas of hydraulics, engines and power, pipe manufacturing, and electronics, comprised of top experts in R&D, production, service, and sales, we completed 137 improvement tasks in 2022 and are in the process of completing 76 additional tasks in 2023.

The (proposed) improvements derived from such activities will be applied to current mass-produced models as well as new models planned for release to achieve dramatic quality improvements that can be felt on the market and by customers.

Quality Innovation TF Operations

Customer Issues

Customer Issues

Quality Issues

Development Issues

Early Sensing,

Quick

Response

Quality is the top priority of HD Hyundai Construction Equipment, where no compromises can be made. To maintain customer trust, we operate a quality control system based on real-time quality monitoring and quantitative indicator management, operate a quality assurance center, and minimize the cost of quality failure to strengthen quality competitiveness by leveraging company-wide capabilities. Global quality information is judged on a daily basis and shared in real time across all divisions of the company. To achieve greater customer satisfaction, we have selected quality posts (Q-Posts) for major regions such as Korea, North America, Europe, China, India, Brazil, and emerging markets and are operating a regional and model-based matrix system to deal with market demands in real time by analyzing information from experts on each equipment model. We have also established a digital quality analysis assurance system to shorten the improvement period, and we are continuously improving the system to proactively respond to the needs of the global market.

From the mid- to long-term perspective, we will further enhance our product quality by upgrading our quality improvement system to take one step further from post-failure improvements to proactive quality activities by recognizing potential failures in advance.

ISO 9001-certified Business Sites

6 locations

Ulsan/Bundang/Yongin/China/India/Brazil

Operation of the Quality Assurance Center

HD Hyundai Construction Equipment is operating the Quality Assurance Center at the Ulsan Campus to strengthen its quality competitiveness. The center is equipped with four measurement rooms and one evaluation room: a material analysis room, an electronic system evaluation room, a parts analysis room, a precision measurement room, and an equipment evaluation room. With the introduction of various new facilities, the center carries out a wide range of tests and evaluations including material analysis, precision measurement, component analysis, electronic system evaluation, and equipment evaluation.

We expect that the in-house analysis of component materials and breakage, which was previously carried out by service providers, and self-verification will speed up the improvement process dramatically and strengthen product quality. Going forward, we will establish and register technical standards based on the data accumulated through analysis, measurement, and evaluation performed at the Quality Assurance Center and use them to improve equipment performance and develop technology.

Digital Transformation

Productivity innovation and safety enhancement using digital and intelligent technologies are occurring at an accelerated rate in the construction machinery industry. As the industrial environment changes as such, construction machinery equipment is evolving from smart equipment that simply supports operators to make their work easier to AI equipment that utilizes AI technology to realize optimal productivity and ensures safety.

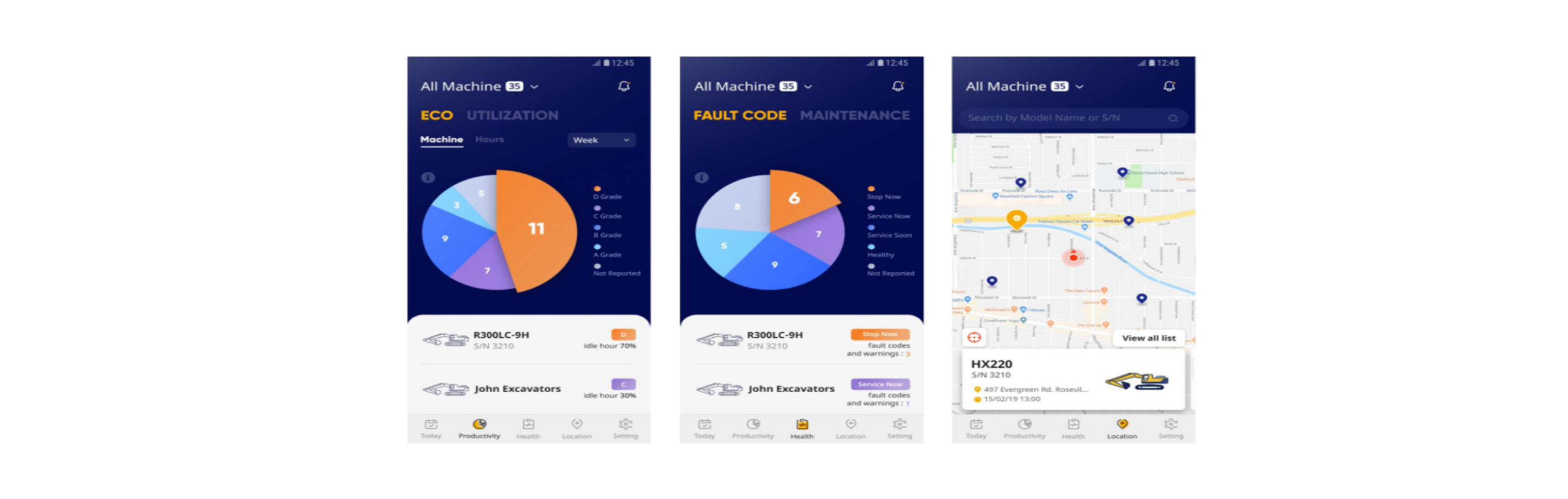

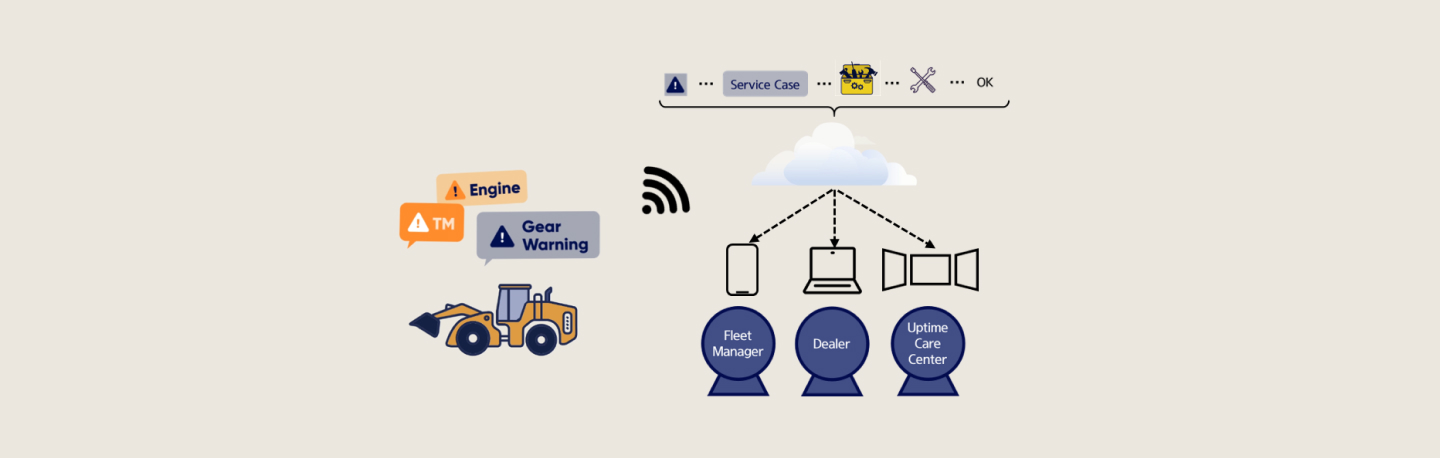

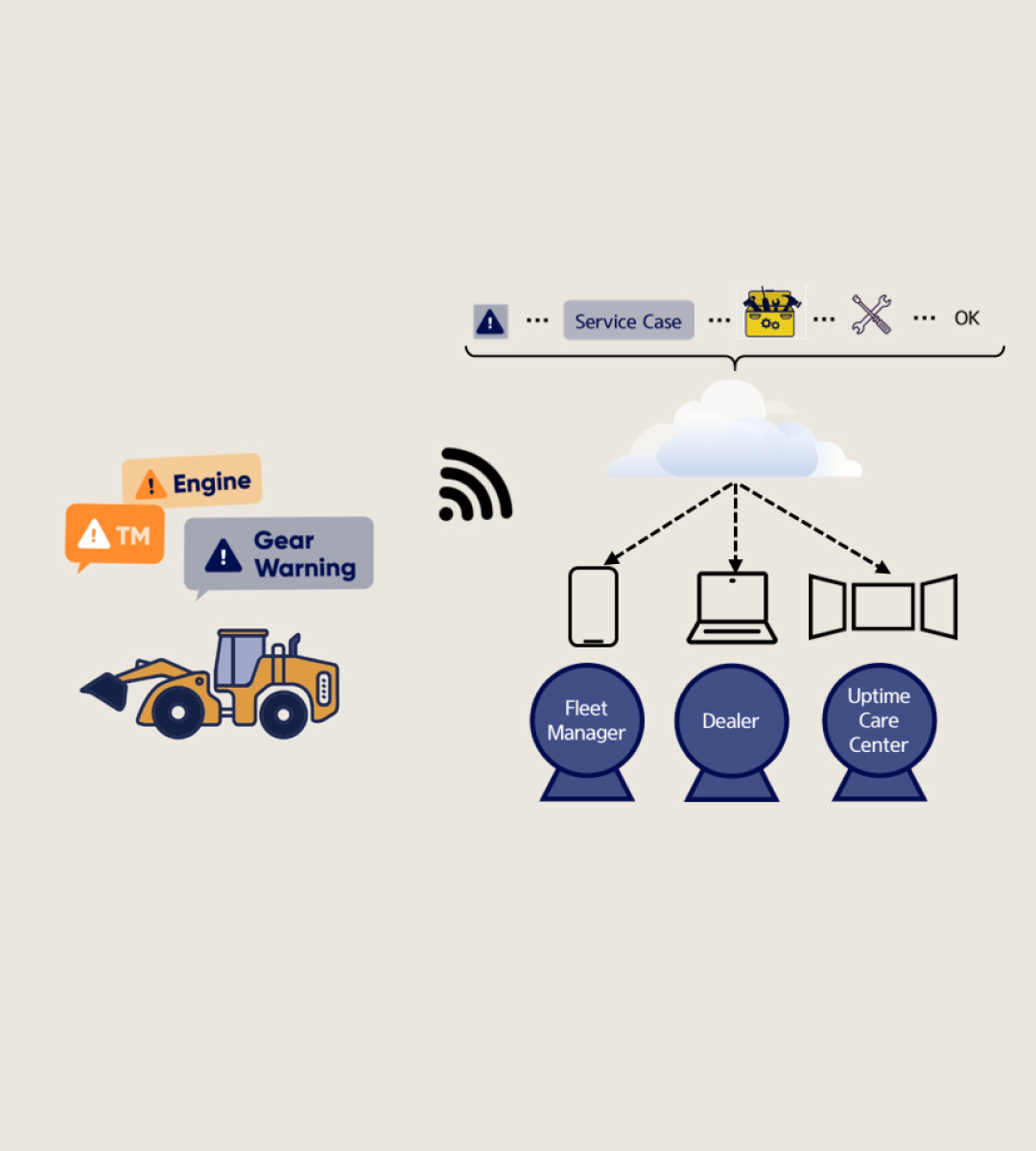

In order to equip ourselves with such AI equipment, we have established a digital technology vision called "Hyundai Connect" and are developing technologies such as Hi ASSIST to support operators, Hi DETECT to enhance safety, Hi CARE to qualitatively and quantitatively improve equipment uptime, and Hi SITE, which can be used to monitor equipment fleet operation status and the results of topographic surveying and analysis of the site.

By leading the development of digital technology in the future, we will provide new experiences and values to our customers, while contributing to the development of a sustainable society by minimizing the cost of infrastructure construction and safety incidents.