HD Hyundai Construction Equipment's mobile website is optimized for portrait (vertical) view.

Safety

Check out the innovative technologies of HD Hyundai Construction Equipment that's leading the global construction equipment industry with astounding technological prowess.

System solutions to prevent safety incidents

Hi DETECT

Solutions for equipment safety

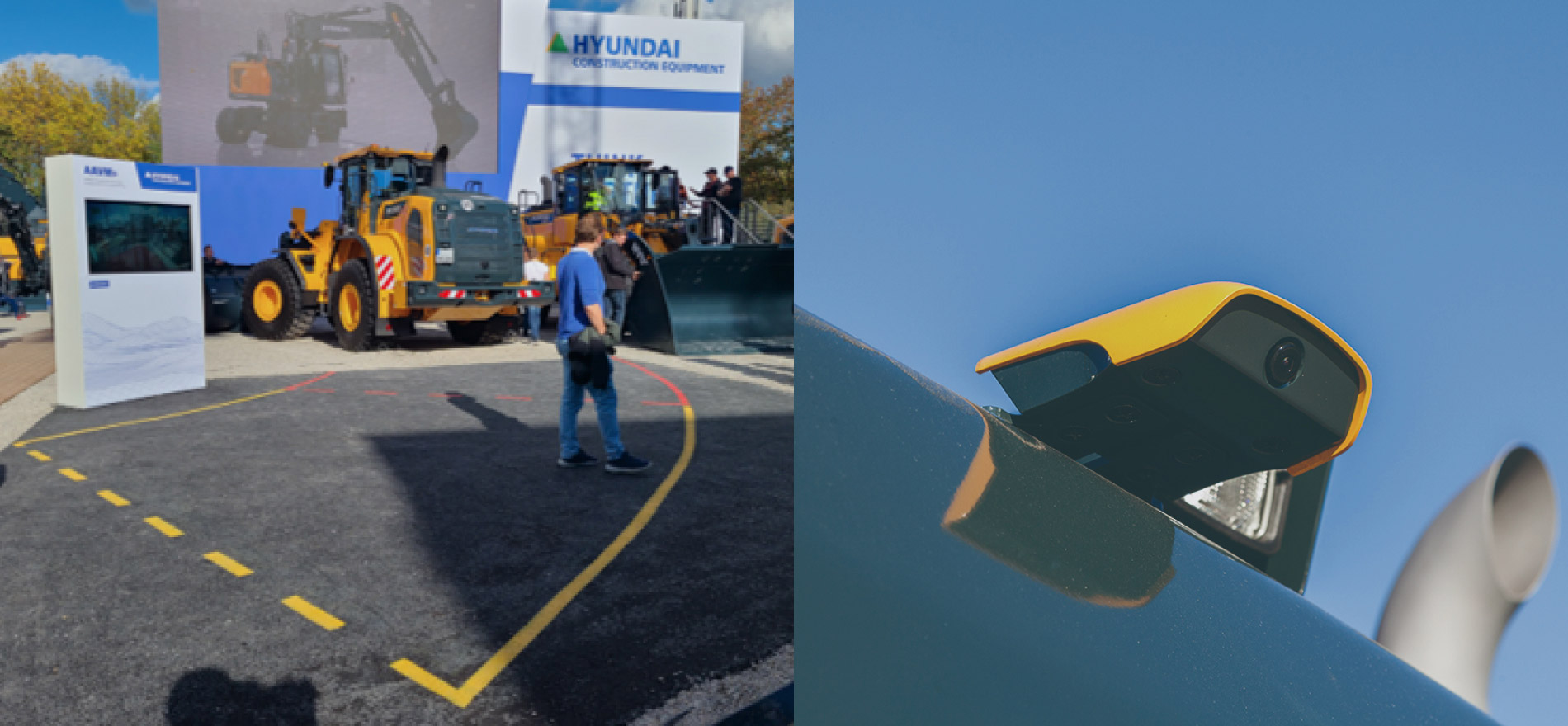

AAVM (Advanced Around View Monitoring)

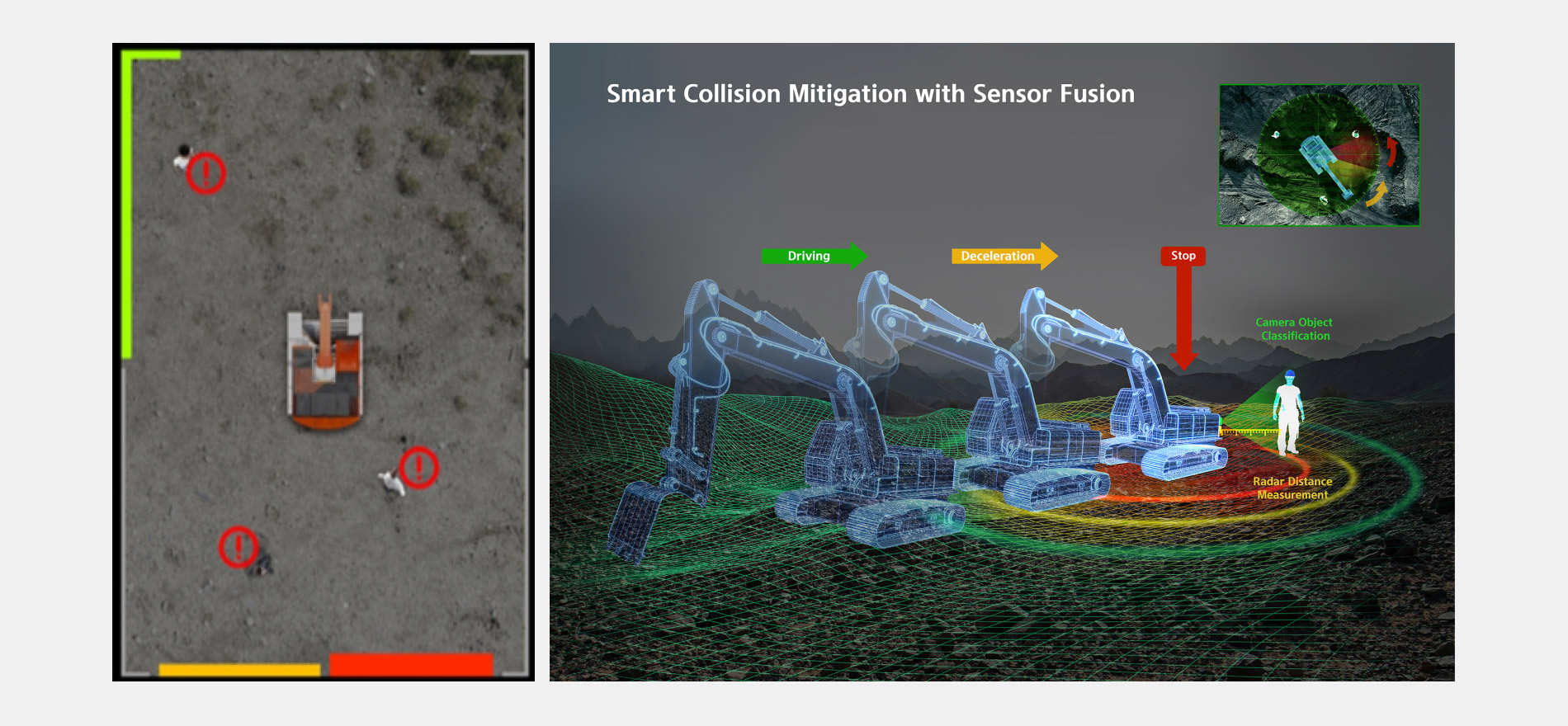

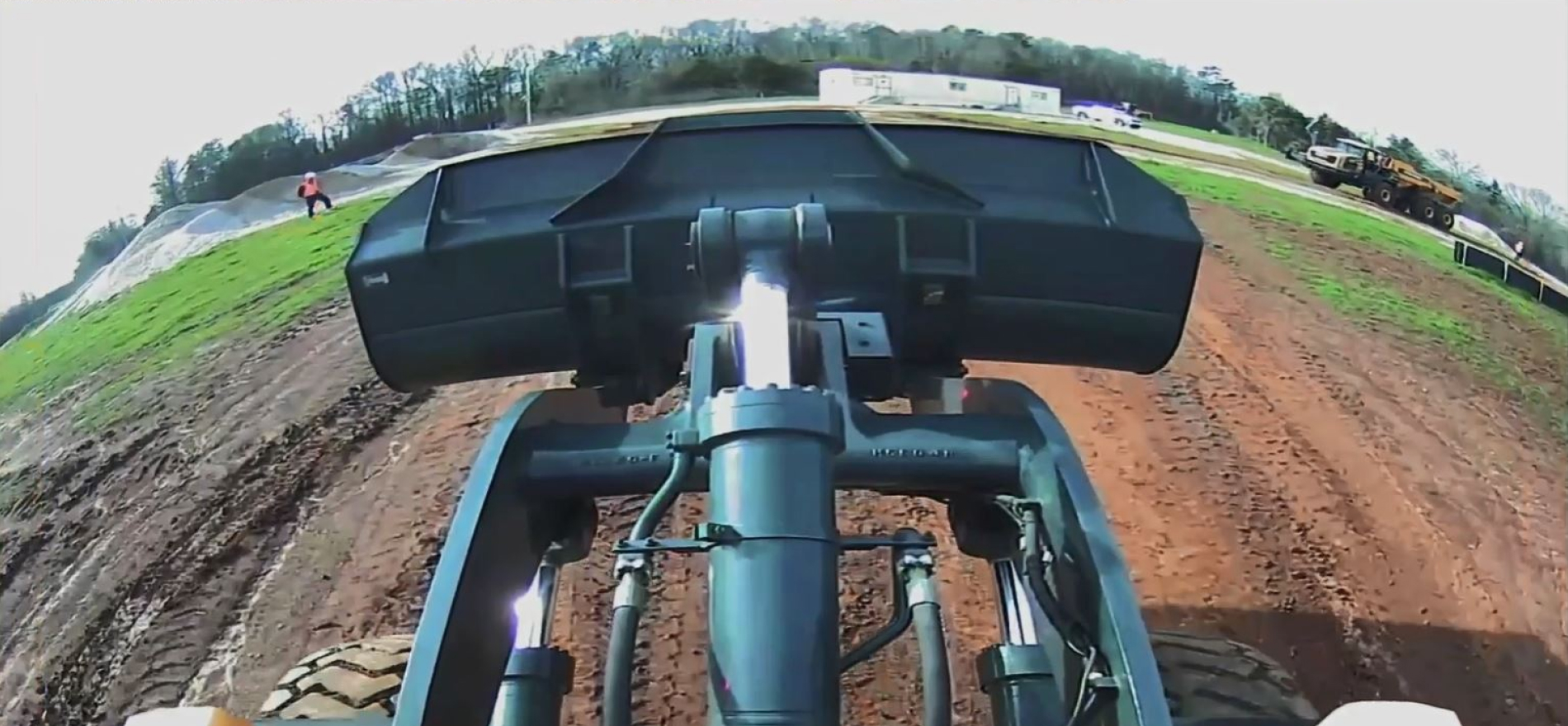

HD Hyundai Construction Equipment was the first company in Korea to commercialize the AAVM system. The AAVM system allows the operator to see the surrounding environment at a glance without blind spots through four cameras mounted on the equipment. To prevent accidents, the monitor displays a warning sign when a moving object is detected within a certain radius around the equipment. To further enhance worker safety, we plan on developing and applying an AI system incorporating sensor (e.g., radar) and camera technology to selectively recognize objects such as pedestrians and trucks and automatically slow down and stop the excavator during turning or driving depending on the level of risk.

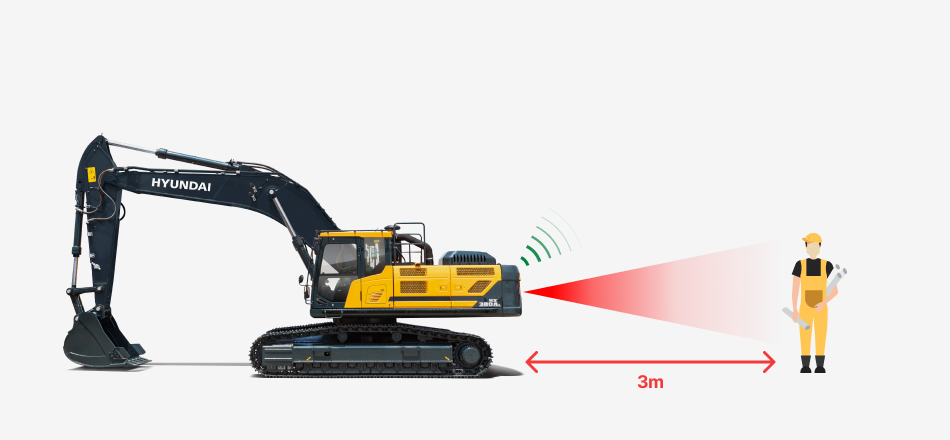

RDS (Rear Detection System)

The RDS detects objects using wide-angle radars installed at the rear of wheel loaders and wheel excavators and warns operators and pedestrians. The radar sensor is highly resistant to external environmental factors, making it possible to detect objects even under low-visibility conditions due to snow, rain, fog, dust, or nighttime operation. It also displays a bar gauge on the secondary monitor that indicates the distance of the detected object and warns the operator with a buzzer sound. In the case of domestically available wheel excavators, external audio warnings reduce safety incidents involving pedestrians.

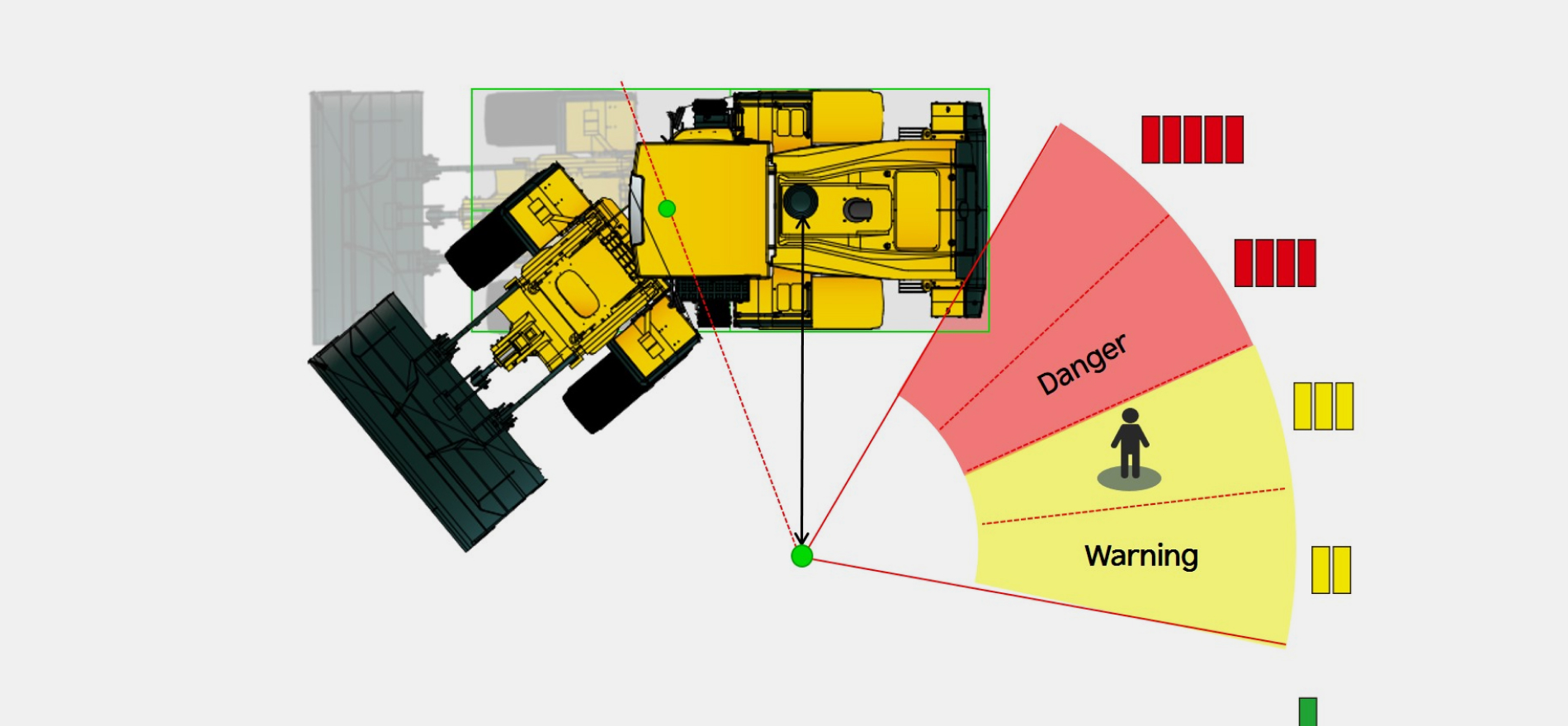

AAVM+ (Advanced Around View Monitoring Plus)

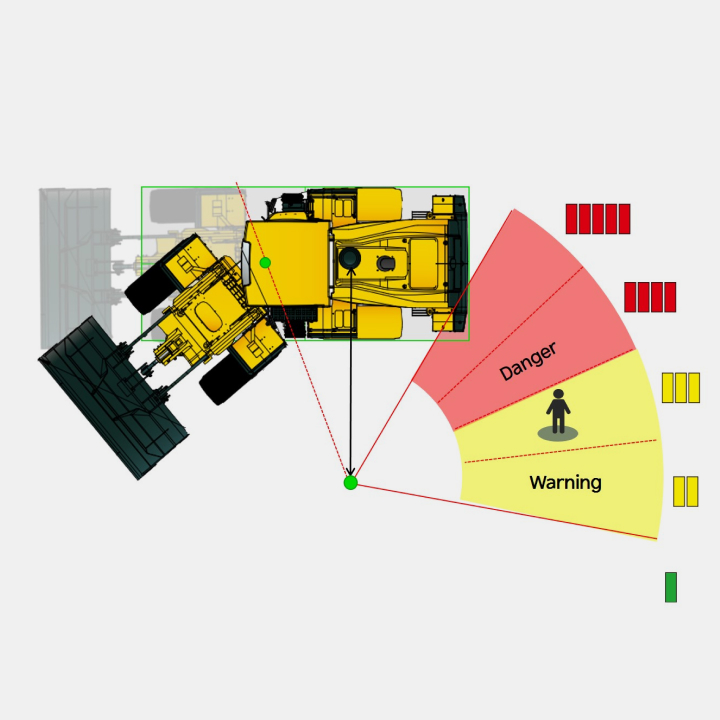

The AAVM+ system has furthered improved the rear-side safety of wheel loaders by incorporating a rear wide-angle radar sensor and a steering angle sensor into the AAVM system. The 180° wide-angle radar minimizes blind spots in the rear, even at the maximum steering angle, and an estimated trajectory is provided when driving in reverse based on the steering angle. By selectively detecting only objects within the expected trajectory, the radar minimizes unnecessary warnings, allowing the operator to work efficiently while reducing the risk of accidents. AAVM+ is a technologically advanced safety system for the construction equipment industry. Unlike similar systems offered by other companies, when an obstacle is detected within a hazard/warning area of interest, the area in question starts blinking to notify the operator. Moreover, the user can set the width and length of the hazard/warning area according to the equipment model and operating environment.

SAVM (Smart Around View Monitoring)

HD Hyundai Construction Equipment's signature safety technology, SAVM, allows the operator to see the surrounding environment at a glance without any blind spots through multiple omnidirectional cameras mounted on the equipment and warns the operator audibly and visually through the monitor when a person is detected nearby. AI technology is used to detect the presence of people when the machine is being driven or turned and even when there is no dynamic movement. When linked with radar, radar detection warnings are also provided to ensure worker safety. HD Hyundai Construction Equipment plans to apply SAVM technology to all of its products and to develop additional features such as stopping the equipment based on sensor technology.

System solutions to prevent safety incidents

Remote Control

The remote control system allows the operator to operate the equipment from outside to improve safety and work efficiency.

The equipment can be remotely controlled using the console method, where it is directly viewed and operated from a short distance away, or the station method, where images from the cameras installed on the equipment can be viewed in real time, regardless of the distance.

The station method promotes work safety in dangerous areas where there is a risk of falling rocks, during demolitions, and at sites that workers should avoid due to pollution or dust. Notably, the station method allows equipment to be operated from a comfortable indoor environment without the effects of noise and vibration at the site, and one operator can remotely operate multiple pieces of equipment.